Exploring the World of Automation: Plc Full Form and Impact of PLC

In the ever-evolving landscape of industrial automation and control systems, the term “PLC” stands as a cornerstone, pivotal in transforming manufacturing processes, enhancing productivity, and ensuring reliability in various sectors. But what is plc full form, and why is it so significant in the world of automation?

PLC full form: Programmable Logic Controller

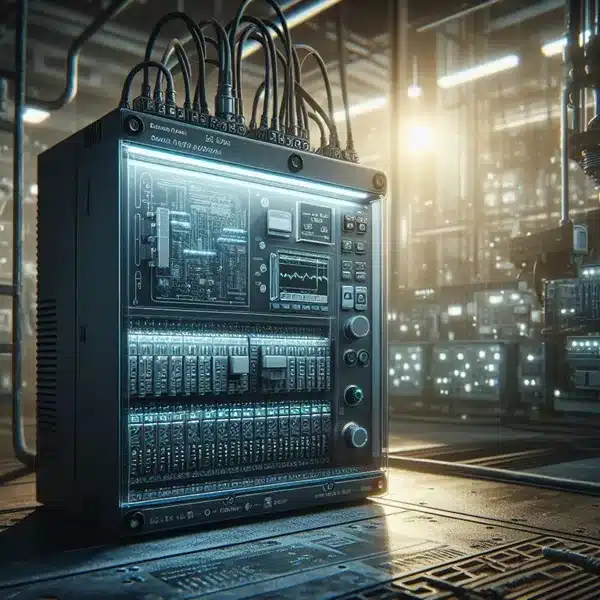

At its core, the full form of PLC is Programmable Logic Controller. This digital computer is specially designed for industrial applications, operating under harsh conditions with features like resistance to vibration, temperature fluctuations, and electrical noise. A PLC’s primary function is to automate specific processes, machine functions, or even entire production lines.

The Genesis and Evolution of PLCs

The inception of PLCs can be traced back to the automotive industry in the late 1960s, with the goal of providing a more flexible and cost-effective alternative to hard-wired relay systems. The advent of PLC technology marked a paradigm shift, enabling industries to easily modify control logic through programming rather than rewiring. This revolution not only reduced downtime and labor costs but also introduced unprecedented levels of control and precision in industrial processes.

How Does a PLC Work?

A PLC works by continuously monitoring the state of input devices and making decisions based upon a custom program to control the state of output devices. Essentially, it can be thought of as a specialized computer that reads inputs (sensors, switches), processes them through a user-defined program, and then outputs commands to machinery or actuators. This process enables automation of tasks with high reliability and speed.

Key Components of a PLC

CPU (Central Processing Unit): The brain of the PLC, responsible for executing control instructions contained in the program.

Input/Output Modules: Interface for the PLC to receive signals from input devices and send signals to output devices.

Power Supply: Converts the main AC to low-voltage DC power required by the PLC internals.

Programming Device: Used to input and modify the PLC’s program. This can be a computer running specific software connected to the PLC.

Applications of PLCs

PLCs are ubiquitous in the industrial world, with applications spanning from the simple control of lighting systems to the complex automation of entire production lines. Industries such as automotive manufacturing, food processing, chemical plants, and water treatment facilities rely on PLCs for operations that require high reliability, precision, and flexibility.

The Future of PLCs in the Digital Age

As we delve deeper into the era of Industry 4.0, the role of PLCs—whose full form is Programmable Logic Controllers—is rapidly evolving, thanks to their integration with cutting-edge technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing. This synergy enhances PLCs’ capabilities, enabling advanced data analytics, predictive maintenance, and remote control functionalities. Such advancements herald a new era in automation and operational efficiency, showcasing the significant impact of understanding PLC full form and their evolving role in modern industries.

Conclusion

The Programmable Logic Controller (PLC) has indeed been a game-changer in the field of industrial automation. Its ability to adapt, control, and monitor the operations of machinery and processes efficiently has not only increased productivity but also paved the way for the advent of smart factories. As technology continues to advance, the role of PLCs is set to become even more pivotal, driving innovation and efficiency in industries worldwide.

In exploring the depths of PLCs, we uncover not just a technological tool, but a beacon of industrial evolution, embodying the relentless pursuit of efficiency and precision in the modern world.