How Drum Lifters Minimize Downtime and Boost Productivity

In manufacturing, warehousing, and logistics organizations, time is often equated to money. Hauling around massive drums is dangerous, protracted, and ineffective. Drum lifters are a smart solution. They are intended to ensure ease in handling of drums and also to eliminate time wastage in production processes. Lifting equipment has become a necessity for businesses, particularly in Malaysia, to enable them to remain relevant in the market.

Decreasing downtime with drum lifters

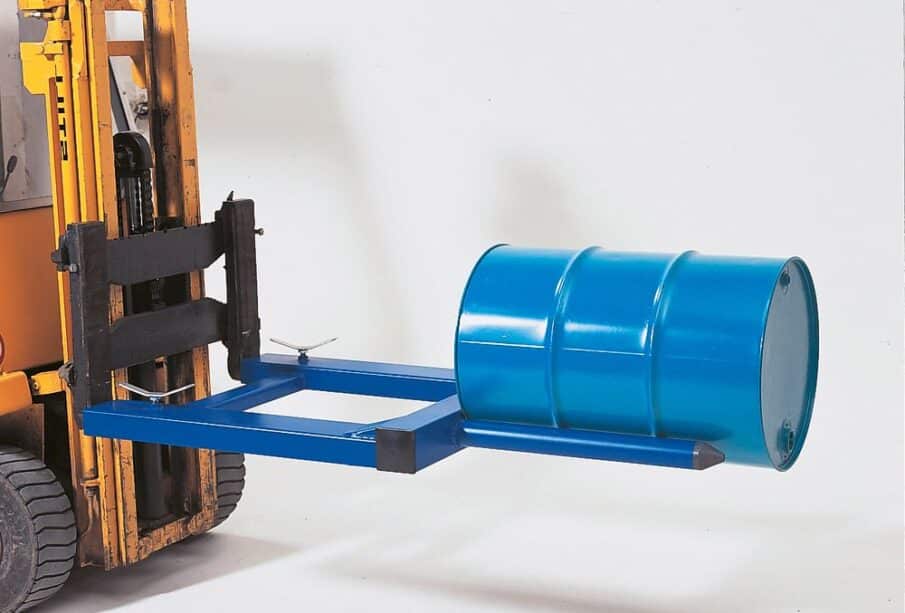

A drum lifter is a unique piece of equipment which is used to lift, transport and set down drums in a safe manner. They apply steel, plastic and fiber drums in their operations. For any application that requires loading, stacking or emptying drums, these tools accomplish the chore more efficiently and safely.

1. Faster Operations

Drum lifters do not have to be moved around manually. This simplifies many processes, making them quicker and cutting down on delays.

2. Improved Safety

The problem with using manual handling is that accidents frequently occur, and people get hurt, resulting in more time out of production. Covers help to minimize spills, falls or damage to the materials so that you have drum lifters for a safer handling process. It also maintains efficient flows in the operations.

3. Streamlined Processes

Using drum lifters does not require the employees to wait for other people or equipment to move drums or their content around. This reduces idle time and ensures that various production lines are being worked on occasionally.

Lifting Equipment in Malaysia Can Enhance Your Performance

However, there is increasing demand for quality Lifting Equipment Malaysia. Just like the drum lifter in Malaysia. Companies understand the importance of spending on quality equipment in order to enhance performance. Local suppliers are available to provide different options to fit various needs in order to provide businesses with the necessary equipment. Increasing productivity with these products;

1. Enhanced Efficiency

Drum lifters are not intended to swing, bounce or jolt in any way. Observations such as these are occasioned by the fact that operations such as moving fluids or stacking drums become easier and faster.

2. Versatility in Usage

In every place starting from the warehouse and going to the chemical plant, drum lifters are applicable. Malaysian businesses, where industries are varied, there it will be very useful.

3. Reduced Employee Fatigue

Lifting, if done regularly, can lead to exhaustion of the muscles, hence reducing the productivity of the workers. That is why drum lifters make it easier to allow employees to deal with other tasks without feeling so tired.

Conclusion

Drum lifters are a significant element of today’s companies. They provide a way of cutting on the operating time to help in making the operations safer. On the same note, they increase employee productivity through optimizing efficiency and thereby lessening physical stress on the workers.